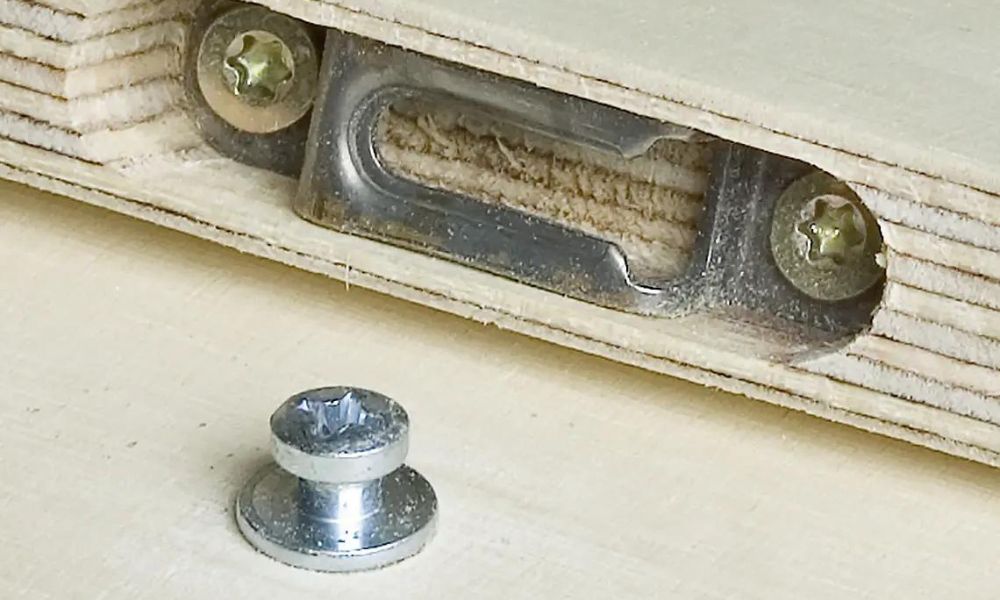

In automotive engineering, fastening components ensure various vehicle systems’ reliability, durability, and precision. Fasteners such as shoulder screws offer unique advantages in automotive applications. In this blog, you can explore the diverse applications of the same in automotive engineering, highlighting their contributions to reliability and precision.

Chassis and Suspension Systems:

Stabilizer Bar Links: Stripper bolts are commonly used in stabilizer bar links, connecting the stabilizer bar to the suspension components. Their precise fit and ability to handle dynamic loads make them ideal for maintaining stability and enhancing handling characteristics. They are frequently employed in stabilizer bar links, effectively connecting the stabilizer bar to suspension components. Their precise fit and capacity to withstand dynamic loads contribute to improved stability, enhanced handling characteristics, and a smoother driving experience.

Control Arms: They are employed in control arms, linking the suspension system to the vehicle’s chassis. These fasteners provide secure connections, allowing precise suspension movement, controlling wheel alignment, and ensuring optimal ride quality. They are integral to possess arms, serving as connectors between the suspension system and the vehicle’s chassis. Secure connections enable precise suspension movement and control wheel alignment, ultimately delivering optimal ride quality with improved handling and stability.

Engine Components:

Cylinder Head Fastening: Shoulder screws find applications in cylinder head fastening, particularly in overhead camshaft (OHC) engines. These screws secure the camshaft carrier to the cylinder head, ensuring precise alignment and proper operation of the camshaft for efficient engine performance.

Timing Belt and Chain Tensioners: They are utilized in the timing belt and chain tensioners to maintain proper tension, ensuring accurate timing and synchronicity of engine components. The precise fit and stability provided by shoulder screws contribute to reliable engine operation.

Electrical Systems:

Connectors and Terminals: Stripper bolts are crucial in securing electrical connectors and terminals in automotive wiring harnesses. They ensure uninterrupted electrical conductivity by providing stable and reliable connections, minimizing the risk of electrical malfunctions.

Grounding Points: They are grounding points for vehicle electrical systems. They provide a secure, low-resistance connection between the electrical components and vehicle chassis, ensuring adequate grounding and minimizing electrical interference.

Transmission and Drivetrain:

Gearbox Assembly: Shoulder screws are crucial in assembling gearboxes and securing components such as gears, shafts, and synchronizers. Their precision and stability contribute to smooth gear shifting and reliable transmission performance. It plays a vital role in the gearbox assembly, providing a robust connection between gears, shafts, and synchronizers. Their high precision and stability ensure seamless gear shifting and dependable transmission performance, enhancing the overall efficiency and durability of the gearbox system.

Axle Connections: They connect axles to the drivetrain components. These fasteners provide the necessary strength and stability to handle the torque and load forces, ensuring reliable power transmission to the wheels. They have a threaded section at one end and a smooth, cylindrical shoulder at the other. This design allows for precise alignment and secure attachment of axles, preventing axial movement and enhancing the overall performance of the drivetrain system.

Conclusion:

Thus, stripper bolts are critical in various automotive applications, ensuring reliability and precision in automotive engineering. From chassis and suspension systems to engine components, electrical systems, interior and exterior trim, and transmission and drivetrain, shoulder screws provide secure connections and stable performance. The precise fit, durability, and vibration resistance offered by shoulder screws contribute to the overall reliability and safety of vehicles on the road. As automotive engineering continues to advance, these screws will remain necessary fasteners, enhancing the performance and longevity of vehicles.