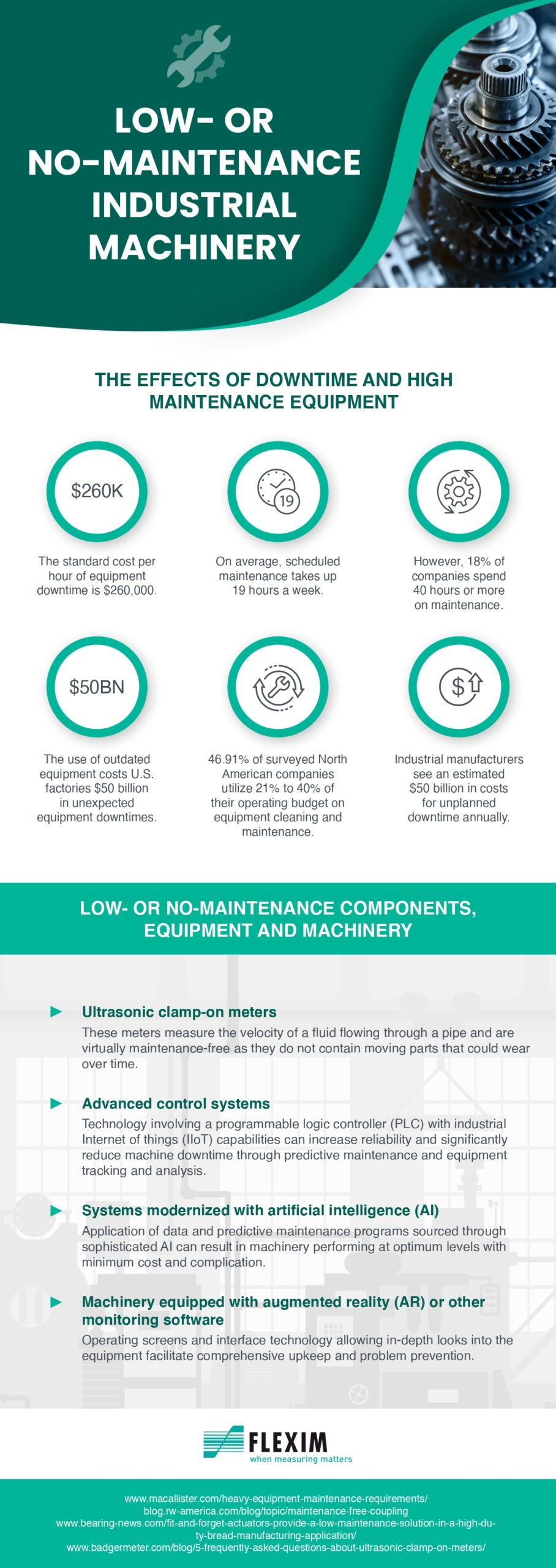

Equipment maintenance can be very costly in terms of both time and money. How is it feasible to maintain competition while being profitable (ROI)? Here, we briefly discuss the technological advancements and administrative strategies utilized to cut down on equipment and maintenance downtime.

By 2026, it is expected that the market for maintenance, repair, and operations would be worth $701.3 billion. Several things contribute to this high cost in industrial settings. Unplanned downtime is primarily caused by outdated resources. According to maintenance experts, unscheduled equipment downtime can result from mechanical failure, operator error, a lack of enough maintenance time, and bad design.

A wonderful approach to save down on maintenance is to use parts that require little to no maintenance. Ultrasonic clamp-on meters are a good example. Due to the fact that they don’t have any moving parts that could degrade over time, these meters are employed in a range of situations, including the water distribution business. They are intended to need little to no maintenance, if any at all.

Another technique to increase ROI is to put a complete preventive maintenance (PM) policy in place. In fact, preventive maintenance was identified as the top priority in 2020 by 76% of industrial businesses. This strategy seeks to spot prospective issues and deal with them before they have a chance to become actual issues. Therefore, PM contributes to lowering downtime, extending equipment life, and raising resale value. The type of machinery, however, affects how much it costs to own the asset overall.

Analytical technologies are also used in predictive maintenance. According to studies, 41% of industrial companies now use this tactic. Despite being costly and new, predictive maintenance is purportedly very cost-effective. According to the US Department of Energy, it can save between 8 and 11% when compared to preventive maintenance. In addition, experts project that by 2024, the global market for predictive maintenance would total $23.5 billion.

What is predictive maintenance (PdM)? PdM evaluates the health of in-service assets and provides data in real-time using specialized software, artificial intelligence, and sensors. By analyzing this data, it is feasible to predict when the asset needs maintenance. This approach aims to potentially lower costs compared to routine or time-based preventative maintenance by only performing actions when necessary.

The chore of managing maintenance is challenging. However, by implementing new technologies, upgrading to low- to no-maintenance components, and employing the appropriate tools for the job, it is possible to extend the lifespan and performance of everyday equipment.

For further information on maintenance and workable solutions, consult the supplemental material.